I have some Autocad data where the objects are constructed as 3D solids, like this:

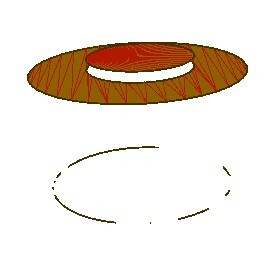

The 3D data is nice for many uses, but I would also like to extract a simplified version for our GIS databases. The Surface Footprint Replacer will generate a nice polygon, but will also remove the elevation and return 2D data.

The 3D data is nice for many uses, but I would also like to extract a simplified version for our GIS databases. The Surface Footprint Replacer will generate a nice polygon, but will also remove the elevation and return 2D data.

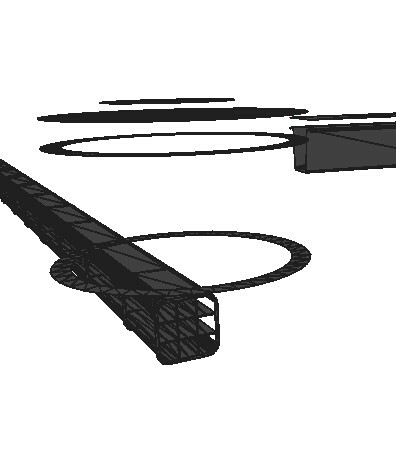

Is there a way to get a footprint that retains the elevations of the "top face" of the solid? I most cases this face is flat, but in some cases, like ducts and pipes, this is not the case.

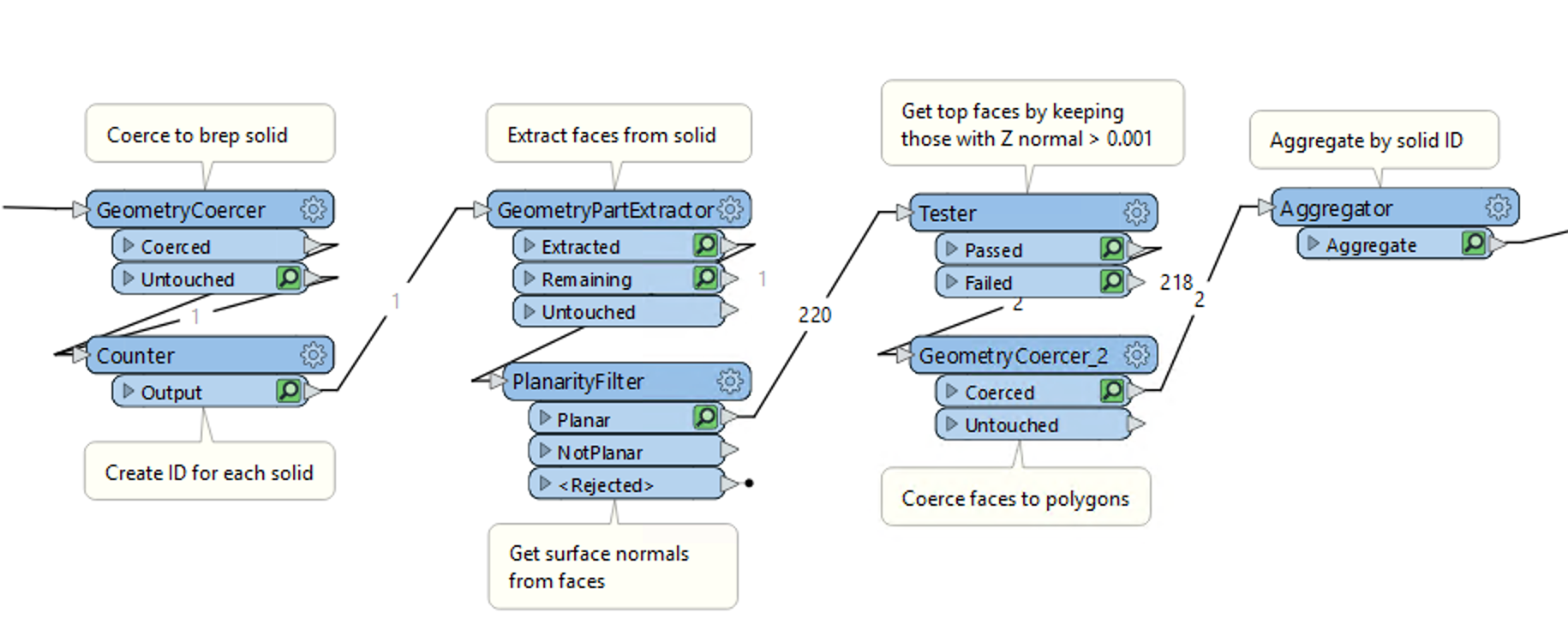

I have attached a sample workspace to illustrate the process

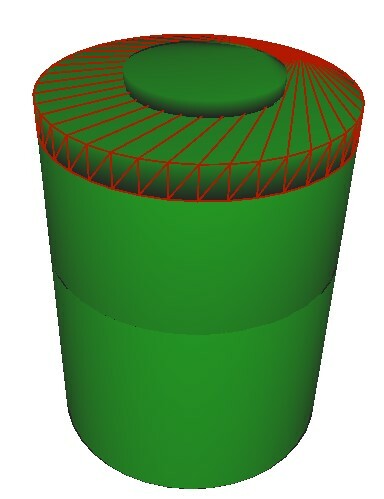

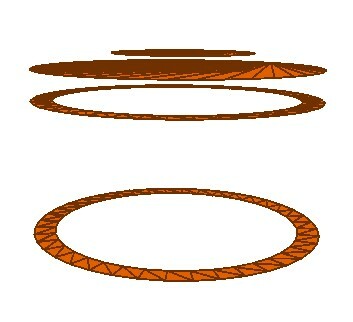

I have attached a sample workspace to illustrate the process The next task would be to get rid of the lower rings (in this case). Ideally, I would want to end up with the two upper surfaces, the top circumference of the manhole and the top circumference of the manhole cover.

The next task would be to get rid of the lower rings (in this case). Ideally, I would want to end up with the two upper surfaces, the top circumference of the manhole and the top circumference of the manhole cover.